How to Choose the Right Cardboard Mailing Tubes for Shipping?

Choosing the right cardboard mailing tubes for shipping is crucial for any business. According to industry expert John Smith, “The right tube can protect your products and enhance your brand image.” Cardboard mailing tubes offer a versatile solution for shipping various items securely. Their sturdiness reduces damage during transit, making them a popular choice among shippers.

However, not every cardboard mailing tube is created equal. Businesses often struggle with options like size, thickness, and design. Some may overlook the importance of selecting the proper dimensions, leading to wasted materials and increased costs. It’s important to think about the type of product being shipped. Fragile items may need additional protection.

Moreover, the environmental impact of packaging cannot be ignored. Companies should consider eco-friendly options that align with sustainability goals. This concern adds another layer to the decision-making process. While cardboard mailing tubes are practical, careful thought is required to avoid common mistakes. A well-chosen tube can make all the difference in ensuring products arrive safely and on time.

Understanding the Different Types of Cardboard Mailing Tubes

When selecting cardboard mailing tubes, understanding the various types is crucial. Different designs serve different purposes. Some tubes have a round shape, while others are hexagonal or square. Round tubes are popular for posters and blueprints. They protect contents better during transit. Hexagonal tubes can stack easily, making storage simpler. Square tubes provide a snug fit for items like rolled-up textiles or paper.

Tips: Consider using a reinforced tube for heavier items. This added strength can prevent damage. Choose a tube with end caps to secure your items further. These caps hold contents in place during shipping.

Another factor to reflect on is size. Not every item fits snugly in standard sizes. Custom sizes are an option, though more costly. It's often better to have a little extra room than a tight fit that risks bending. Additionally, think about the weight of the tube itself. Heavy tubes may add shipping costs. Lighter options can seem more economical.

Tips: Always measure your items before selecting a tube. A tape measure can provide accurate dimensions. Allow extra space for padding. Avoid delays with accurate sizing.

Factors to Consider When Choosing Cardboard Mailing Tubes

When choosing cardboard mailing tubes, several factors come into play. Material strength is essential. You need tubes that withstand the rigors of shipping. A flimsy tube can lead to damaged items. The weight of your package is also crucial. Heavier items may require sturdier tubes. Lightweight tubes might not offer adequate protection.

The diameter of the tube must match your items. A tube that’s too small can crush your contents, while one that’s too large could allow shifting. Consider the length as well. Oversized tubes waste space and increase shipping costs. Additionally, think about the closures. Secure ends prevent items from slipping out.

Eco-friendliness is a significant aspect today. Selecting recyclable materials reflects a commitment to sustainability. However, it’s essential to balance eco-friendliness with reliability. Sometimes, the most sustainable option may not provide the necessary protection. Reflect on what matters most for your shipment.

Factors to Consider When Choosing Cardboard Mailing Tubes

Measuring Dimensions for Optimal Fit in Shipping

Choosing the right cardboard mailing tubes can make or break your shipping experience. One key factor is measuring dimensions accurately. Measure the length and diameter of your items to ensure the tube’s size fits well. A snug fit is important; it prevents movement during transit and reduces the risk of damage.

When in doubt about size, try a few mock-ups. Use regular cardboard to simulate the tube. This way, you can check how well your items fit. If you find that items are too loose or tight, adjust accordingly. It’s crucial to have a plan that accommodates various item sizes, which can be challenging.

Tips: Always account for any protective padding you might use. This can change the overall dimensions. Also, think about the weight of the items. Some tubes may not support heavier products well, leading to potential issues. It’s easy to overlook this, but weight matters more than you think. Keep these factors in mind to make the right choice.

Evaluating Thickness and Strength of Cardboard Tubes

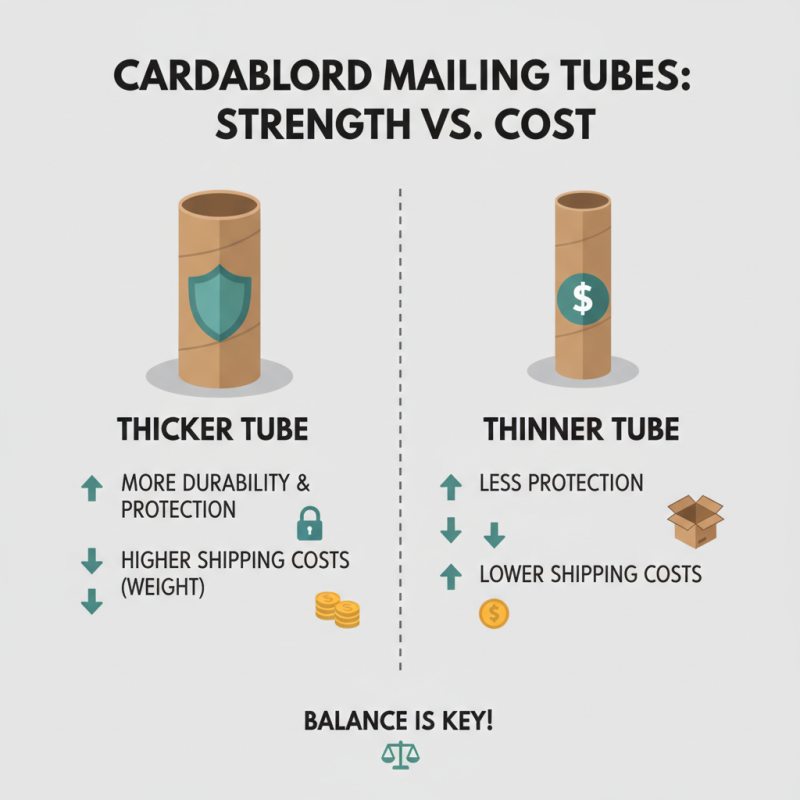

When selecting cardboard mailing tubes for shipping, thickness and strength are critical factors. The right tube protects your items during transit. A thicker tube often offers more durability. However, it may result in higher shipping costs due to weight. Balance is key in your choice.

Check the tube's wall thickness carefully. A standard thickness level is around 0.1 inches. Thicker tubes may seem more secure, but they can also be cumbersome. Investigate your product’s needs. Are you shipping posters, blueprints, or fragile items? Each requires different tube strengths.

Testing the strength of your chosen tubes is also advisable. Try squeezing the tube gently. If it collapses easily, it won't withstand shipping. Support your items with internal packing materials. Using adequate cushioning can also help. It's essential to reflect on your shipping strategy. Are you prioritizing safety, cost, or both? Consider all aspects before making a decision.

Sourcing Quality Cardboard Mailing Tubes from Suppliers

When sourcing quality cardboard mailing tubes, it’s important to consider several factors. Start by evaluating the suppliers' reputation. Look for reviews and customer feedback. Avoid those with consistent negative remarks. Quality matters, especially for fragile items.

Next, assess the material of the tubes. Some may look sturdy but lack proper thickness. Choose tubes made from recycled cardboard for environmental responsibility. Look for the option of different sizes. Not every item fits into standard dimensions. Custom sizing can save space and reduce shipping costs.

Lastly, inquire about the manufacturing process. Understanding how the tubes are made tells you a lot about their reliability. Some manufacturers may cut corners, which can jeopardize your shipment. Pay attention to the way they pack their products, too. If they use flimsy packing materials, question their overall quality. It’s better to do thorough research than to face issues later on.

Related Posts

-

Unlocking Creative Packaging: Why A0 Postal Tubes Are Essential for Art and Print Professionals

-

Overcoming Challenges with Carton Tubes: Solutions for Common Issues

-

The Ultimate Guide to Choosing the Best Tube Mailing Boxes for Your Business Needs

-

Top 10 Tips for Choosing the Best Mailing Tubes for Your Shipping Needs

-

Top Heavy Duty Mailing Tubes for Secure Shipping and Storage Needs

-

Top Heavy Duty Mailing Tubes for Secure Shipping and Storage Solutions